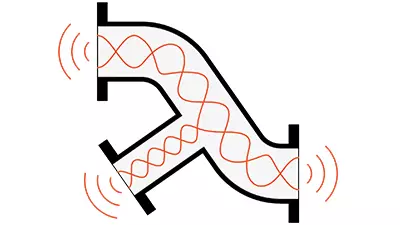

Waveguides

Electroformed Waveguides

Electroformed waveguides direct and control electromagnetic energy.

- Complex Seamless Structures

- Tight Tolerances & Sharp Corners

- Accurate Surfaces & “Grown-In” Features

- High Purity Low Stress Materials

Build-to-Order Waveguides

Electroforming has a high potential for the reproduction of complex shapes. This additive manufacturing method is very effective when requirements call for tight tolerances, seamless structures, or accurate surfaces with sharp corners and edges.

- Composed of pure copper (typically with brass flanges), may be nickel and gold plated

- Custom-manufactured mandrels accommodate any cross-section profile specification

- Special features may be “grown-in” during the plating process

Our electroforming process allows high-precision duplication of a mandrel and therefore permits quality production—at low unit costs with high repeatability and excellent process control. Using this additive manufacturing method, waveguides can reduce the total number of components required for a waveguide assembly.

Need a Custom Electroformed Waveguide?

Custom Dimensions Available

Custom Waveguide Manufacturing

Our vertically integrated advanced manufacturing facility offers comprehensive in-house capabilities for developing custom build-to-order electroformed waveguides. Within our 62,000 sq. ft. service center, we provide thin film coatings, electrodeposited platings, applied machining, and various support services to manufacturer our electroformed components.

Waveguides are typically used to interconnect transmitters and receivers (transceivers) with antennas or transfer electromagnetic power efficiently from one point in space to another. They act as electrical transmission lines for circuits operating at frequencies where the wavelength of the electromagnetic waves is of the same order as the circuit itself. Optiforms manufactures these metallic conductors using our additive manufacturing process called electroforming to produce complex, seamless waveguides with accurate surfaces and tight tolerances.

Electroforming Process

The electroforming manufacturing method generates an exact copy via replication in metal (typically nickel) of a master mandrel by a process called electrodeposition. Specific benefits of electroforming are low unit costs, exact atomic scale, repeatability and excellent process control for quality. Often times the design engineer will find electroforming is preferred for many applications requiring a complex true geometric shape form factor, thin walls, and high repeatability.