Capabilities

additive manufacturing process

capabilities: electroforming

Optical Reflectors to Non-Imaging Optics and More

Electroforming is a process that creates precise metal components by using electrolytic deposition of metal onto a mold, referred to as the mandrel.

Electroforming can be used to create optical reflectors of various shapes and sizes, such as parabolic, elliptical, or spherical to non-imaging optics that transfer light from a source to a target with optimal efficiency and desired distribution.

Application Specific

With electroforming, you can:

– perform ultra-precision processing and replicate the shape and surface of the mandrel with high fidelity.

– adjust the physical properties of the deposited metal, such as hardness, strength, ductility, and conductivity.

– make parts with complex shapes and high aspect ratios that are difficult or impossible to achieve by other methods.

– reduce material waste and save costs as only the required amount of metal is deposited.

– produce parts with low stress and no tool marks that have excellent mechanical and optical properties.

multi-axis machining

capabilities: cnc machining

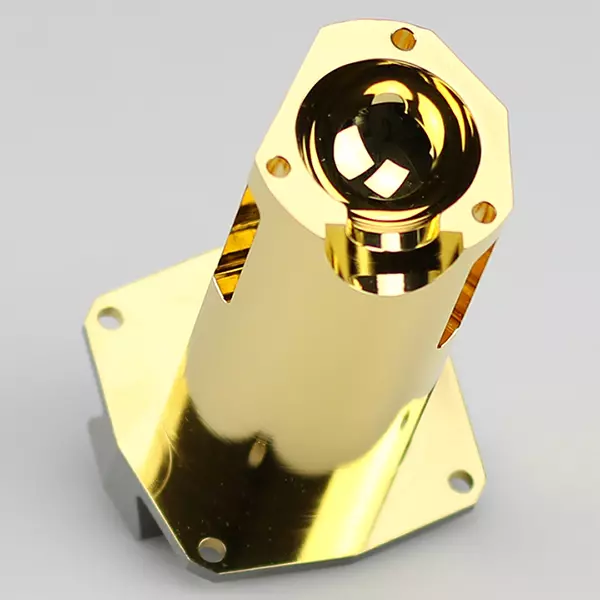

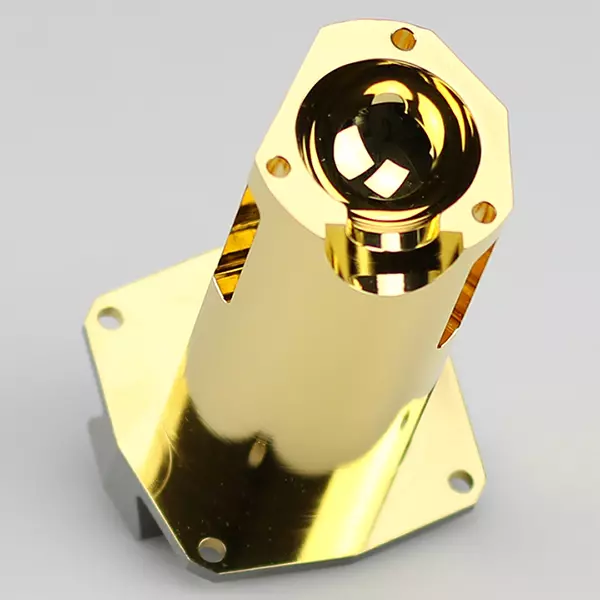

Integrated Dewar Cooler Assembly (IDCA) Components

- Cold Shields

- Window Housings

- Cold Fingers

- Customized Apertures

- Thermal Insulators

Electronics Chassis

Chassis for Communnication and Telemetry Systems

Custom Machined Components

Various Capabilities for Custom Components

Please Complete the Form:

Thin Film optical coatings

capabilities: Physical Vapor Deposition

Broadband Metallic Coatings

Bare Gold, Protected Gold, Protected Silver, Aluminum SiO2, Aluminum MgF2

Enhanced Metallic Coatings

Enhanced Rhodium, Enhanced Aluminum, Enhanced Gold, Silver Reflectance

Ultraviolet Coatings

Aluminum MgF2, Enhanced Aluminum for UV, Deep UV with IR Absorber, UV Dichoric Cold with IR Absorber

Various Electroplating options