Aconic Reflectors

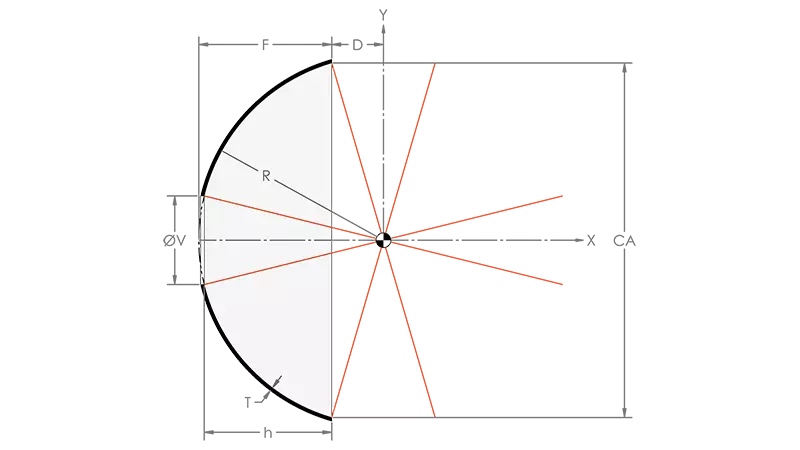

Aconic Reflector Diagram

An electroformed aconic reflector is a light energy reflector that is not based off a mathematical curve.

- Can produce a tapered beam for use as a flood light

- Stock reflectors are coated with electrodeposited bright rhodium.

- Surface Enhancements: Optical Coatings

Optiforms Aconic Reflectors

| Part Number (Click to View PDF) | EFL (in) | EFL (mm) | F (in) | F (mm) |

|---|---|---|---|---|

| OAP 5 | 0.400 | 10.16 | 0.200 | 5.08 |

| OAP 10 | 1.000 | 25.40 | 0.400 | 10.16 |

| OAP 19 | 1.500 | 38.10 | 0.750 | 19.05 |

| OAP 25 | 2.534 | 64.36 | 1.000 | 25.40 |

| OAP 38 | 3.000 | 76.20 | 1.500 | 38.10 |

| OAP 60 | 4.669 | 118.59 | 2.350 | 59.69 |

| OAP 76 | 6.000 | 152.40 | 3.000 | 76.20 |

| OAP 178 | 14.000 | 355.60 | 7.000 | 177.80 |

Stock reflectors are coated with electro-deposited bright rhodium.

*F = Flange

*NV = No Vertex

Need a Custom Aconic Reflector?

Custom CA and V-DIA Dimensions Available

Electroforming Process

The electroforming manufacturing method generates an exact copy via replication in metal (typically nickel) of a master mandrel by a process called electrodeposition. Specific benefits of electroforming are low unit costs, exact atomic scale, repeatability and excellent process control for quality. Often times the design engineer will find electroforming is preferred for many applications requiring a complex true geometric shape form factor, thin walls, and high repeatability.